https://www.disneyresearch.com/project/mechanical-characters/

POST 10

physical math

https://3dprint.com/52139/3d-printed-math-manipulatives/

http://makezine.com/projects/make-42/fun-with-flexibles

math

https://sketchesoftopology.wordpress.com/2014/04/25/mathematics-with-3d-printing/

https://www.simonsfoundation.org/multimedia/3-d-printing-of-mathematical-models/

POST 9

Filaments!

http://www.esun3d.net/product.aspx?TypeId=2

http://www.filamentexpress.com/

New Stuff!

PETG (ABS alternative)

and

Nylon

by FilamentExpress

FOR Ultimaker (2.85mm)

230 degrees

NO heated base

No fan

Use blue tape on base

(50mm/sec extrude)

POST 8

We are now entering the final Phase! Please write a short post reflecting on Phase 1 and 2, and brainstorm as to how you might combine your reflections and work from each phase into your final project. Also, start working on your final project. It’s never too early!

in between phase one and two I found myself experimenting with other machines within our craft room and found much pleasure in learning how to use them. though i do wish i had the time now to truly master and possibly troubleshoot the machines. Being able to repair and understand the inner/outter workings of a machine is fairly important as it can save you time and energy at a later time. Now that our 3D printer is malfunctioning, maybe I will be able to troubleshoot and understand the printer even more than before.

Edit: Never mind @spencer fixed it. #schemefoiled

As for phase two, i came to reflect on the powerful uses of a machine like the 3D printer. With focus on education rather than manufacturing, I came to learn about the applications that makers and educators have devised to incorporate the presence of a 3D printer into a classroom. it was interesting to know that the integration of new technologies are have been oppose with few or even valid reasoning. Their is plenty of evidence showing that current practices are important but require a push forward to be much more effective than they once were.

How to combine the work from phase one and phase two?

I would like to experiment with different materials on a 3D printer ( and maybe the laster cutter) to create items that might help some one understand how items are assembled; like when creating parts of different material that will fit into each other and have different amounts of stability or use. Maybe using different material combinations on a interactive plane that encourages experimentation.

kinda like a mix and match activity, or a puzzle.

Though making a sculpture using different materials and parts might be super cool too! snap on and snap off elements to add or take from it.

of course this might be a prototype, but i would actually enjoy more than a prototype or even size limitations. I would also like to branch out to STL printers as well.

we shall see.

POST 7

Alexis Trevizo

Professor Arlene Ducao

Digital Fabrication

5 April 2016

Maker Spaces in Education

As technology has evolved, it has infiltrated every part of society.

From business spaces, to medical fields, technology has helped to advance

countless fields. One field that is currently debated, however, is the

educational space. While some believe that technology should be taught at the

youngest age possible, others are hesitant to take the next step in allowing

the maker movement to spread to the classroom.

To clarify, the maker movement is not just the embrace for 3D printers

and other computer aided design projects. The maker movement is the idea and

embrace of making anything. The definition is so broad that paper craft,

sewing, gardening or even making an ice cream sundae can be considered to be a

part of the maker movement (Martinez). What allows making an ice cream sundae a

possible entity in the maker movement is not the just the act of making the

sundae, but also the process of before and after the creation of the sundae.

Through it may seem like common knowledge, creating anything requires research

and development. A maker must then apply

what they have learned to further iterations of a project, making the next

sundae even tastier than the last.

Yet, it has been argued that our technological advancements are not

helping us evolve in all aspects of living; specifically, within the realms of

education. Many continue to believe that the education systems used today are

considered 20th or even 19th century forms of practice where

students are expected to learn by sitting and listening to an instructor and

then regurgitating lesson on exams. Rather than encouraging new ideas that feed

the technological movements of today, the education system breeds reiteration

of previous ideas. Although this is a common argument, this is not the case with

the maker movement educational institutes and work places. Instead, these

institutions are steering away from the models of the past, hoping to stimulate

creativity and innovation. In the cases with schools that implement these

alternative models, they are even adopting and implementing the ideals of the

maker movement.

Traditionally, schools allow for very little experimentation and don’t

take failure too kindly. Since success is rewarded, failure is typically deemed

as a disturbance in the learning environment. Failing in a traditional

classroom is considered to be omen or even taboo amongst parents and students alike.

Unlike a traditional setting, an education system that venerates failure, such

as the maker ideology, could better help students improve in the future. With innovations such as the 3D printer, maker

culture allows students to quickly ideate and prototype their ideas when it

comes to experimental based lesson plans that require a more hands-on approach.

However, some argue that use of a makerspace in education is simple not

feasible. One primary argument fitting under this category, is that schools,

especially public schools, simply cannot afford to have a makerspace in their

school. According to previous business models, a makerspace can cost up to

$80,000 dollars a month at most (Artisan’s Asylum, Cavalcanti). Although this

price is defined by a business motive, it still portrays how costly the maker

movement can be for small school districts hoping to implement it. The $80,000 price

tag comes from this space’s rent (which is 75% of the expense), hardware,

software, insurance, utilities, maintenance staff. What this opinion against

the use of maker spaces in schools does not take into consideration, however,

is that for schools, these expenses would already be accounted for. As for the

other expenses, many like Sylvia Martinez suggest that maker culture can be

implemented with little extra budget adjustment. In fact, Martinez even

stresses that staffing and maintenance of the space should be entirely managed

by members already employed by the school since maker culture encourages participants

to collaborate with each other. With this method, teachers would not only learn

about the new machines but also learn alongside their students.

For students, the maker culture provides access to a greater learning

experience applicable to spheres beyond the specific maker movement. The

problem solving and the research behind it can easily be applied to any

subject. For example, in a technology school in Georgia, an after school maker

space program allows students to create models for vehicles on software that

would normally not be available to students of their age. Rather than

specifically instructing the students, he allows them to explore the software.

These vehicles are then placed in testing chambers, and then raced against one

another. Regardless of whether or not the students win or lose, they are then

able to go back and redesign their cars, and test them again (Stager). This

process, commonly called the iterative process, has often been excluded out of

the classroom setting until higher education. With the maker movement, however,

the ability to quickly reiterate provides students with exposure to the

iterative process, which is not only important to STEM fields, but also to

liberal arts. Rather than testing a student’s ability to memorize, it allows

them to learn from their failure, and to benefit from the process.

Although the maker movement in schools seems perfect for schools, further

concern is shown regarding how to use maker culture within educational

institutes. In on experiment, two different groups of students were granted

time after school to use 3D printers. One group was given an end goal of

creating a method of education to help students around the world, while the

other group wasn’t tasked at all. Both groups had no prior experience with 3D printing

or the skills required to operate one. Both groups sectioned off into designers

and printers. Students from both groups began designing things to print while

others scoured the internet to learn how to use a 3D printer. The tasked group then

used different methods to add brail to items they created and designed, while

the other group focused on simple items they found or partially created, most

of these being key chains and phone cases. While the tasked group was able to

create a range of objects with brail implantations in additional sessions, the

other group continued to create items like key chains, which they would then

attempt to sell to other students.

Although both groups learned different skills in order to operate the

machines, the untasked group became a small manufacturing plant as opposed to

the other group that effectively solved a serious problem. This experiment

demonstrates how opposition about the maker movement can derive from it’s

capitalistic background. The capitalistic motivation becomes more and more

present with services such as 3D hubs or even e-commerce sites like Etsy, where

handmade objects are easily marketable. Another opposing opinion thinks of the

tools within a maker space becoming expensive toys for children to destroy and

play with. Although any parent with a young child can sympathize with this

view, this “destructive play” in the eyes of the maker movement is considered

experimentations and testing. With the freedom to play, tinker, and analyze

tools within a space; students are given the opportunity to experiment freely

while learning the function and capabilities of tools or object around them.

However, it is still important to keep in mind the direction which students may

take while learning. The tasked group was considered successful in their

efforts because they had guidance form the prompt to help direct their creativity

and still allow them to experiment with limitations in mind. Makerspaces should

not be installed without proper guidance of the students in order to create the

best learning environment possible.

Despite the arguments against maker spaces, the benefits outweigh the

conflicts presented. Maker spaces offer a better system of learning than what

is traditionally presented in schools, encourage young students to immerse

themselves in technology, and promote a creative mindset. Moreover, they give

students the opportunity to learn at a very young age what would normally be

taught decades later in their life. With the tools to learn from their mistakes

and work towards creative solutions, students exposed to maker spaces are at an

incredible advantage for not only their individual development, but also the

development of the rest of society.

Works Cited

Anderson, C. (2012). Makers:

The new industrial revolution. New York, NY: Random House.

Anderson, C. (2013, April

16). The Maker Movement: Tangible goods emerge from ones and zeros. Wired.

Retrieved from http://www.wired. com/2013/04/makermovement/.

Cavalcanti,

Gui. "Model Makerspaces: Creating a Business." Make:.

N.p., 4 June 2013. Web. 6 Apr. 2016.

Deloitte,

C. "Impact of The Maker Movement." Deloitte Center (n.d.):

n. pag.MakerNews. Web. 6 Apr. 2016.

"Education." Maker

Faire. N.p., n.d. Web. 6 Apr. 2016.

Gershenfeld,

Neil. "How to Make Almost Anything: The Digital Fabrication

Revolution." Foreign Affairs 91.6 (2012): 43-57. JSTOR.

Web. 06 Apr. 2016.

Groff,

J. S. (2013). Expanding our “frames” of mind for education and the arts. Harvard

Educational Review, 83(1), 15–39.

Hatch, M. The Maker

Movement Manifesto: Rules for Innovation in the New World of Crafters, Hackers,

and Tinkerers. Print.

Jo,

Wonjin. "Introduction of 3D Printing Technology in the Classroom for

Visually Impaired Students.” Practice Report (2016): 1-8. ebscohost.

Web. 05 Apr. 2016.

"Makerbot

in the Classroom." Makerbot. N.p., n.d. Web. 6 Apr. 2016.

Martinez, S. and G. Stager. Invent

to Learn: Making, Tinkering, and Engineering in the Classroom. Print.

Martinez,

S., and G. Stager. "The Maker Movement: A Learning Revolution."ISTE.

N.p., 21 July 2014. Web. 6 Apr. 2016.

Morozov,

E. "Making It." NewYorker. N.p., n.d. Web. 6 Apr. 2016.

Rotman,

D. "The Difference Between Makers and Manufactures."TechnologyReview.

N.p., 2 Jan. 2013. Web. 6 Apr. 2016.

Stager,

G. "What's the Maker Movement and Why Should I Care?"Scholastic.

N.p., 2014. Web. 6 Apr. 2016.

POST 6

Alexis

Trevizo

Digital

Fabrication

Prof.

Arlene Ducao

03.24.16

Maker Education

To begin, I originally wanted to write

about the possible critiques that educational institutes may have on the maker

movement. Specifically the installation of expensive equipment and materials

such as desktop CNC machine and 3D printers. I wondered how they could hurt an

institute in a financial or educational manner. These thoughts and wonders came to be shortly

after I traveled to the Makerbot Manufacturing plant in Brooklyn with my

Digital Fabrication class at New York University. The words of our tour guide,

Gina, alarmed me after one of my classmates asked about their target clientele.

The targets being large manufactures, creative companies and educational

institutes. Gina had briefly mentioned that higher education institutes didn’t seem

to need a bombardment of advertising to be convinced that purchasing a Makerbot

3D printer. Yet, “lower” institutes -like middle school and elementary- need a

much firmer push. She explained that many of the schools needed further

education on the printer. Makerbot achieves this a basic education program that

shows how easy it is to use their products and thus hoping to convince schools

that purchasing a 3D printer from Makerbot is the best decision that a school

can make. When asked to elaborate on the educational program she mentioned

basic operation, Gina suggested the were teaching educators the basic functions

of the printer. However, when it came to the applications of a 3D printer she

was unclear and eluded to it being helpful with math or science in one way or

another.

To hear a higher level manager Makerbot

vaguely speak about their own products capabilities and uses in an educational

institute was rather alarming. I was in

fact uncomfortable to know that not even the manufactures didn’t know what to

do with a 3D printer ( other just print “stuff” ). This concerned me because it

seemed that Makerbot was having a hard time selling their product to the

general public. With this I walked away

from Makerbot wondering how schools felt about companies like Makerbot desperately

pressuring them to purchase 3D printers. I felt that the presence of a

corporation in a educational institute wasn’t idea for an educational system as it may force pressure schools to cut corners

in other departments. However I found

that I was only assuming that school and other institutions were concerned with

the negatives a 3D printer and the Maker Movement might bring to education.

Immediately I went to work searching for the possible criticisms in of the

Maker Movement or Maker Culture in the education system.

The search for those who apposed the

Maker Movement was rather difficult as most searches lead to the educational

benefits of the Maker Movement. I chose to ignore the results as they weren’t

quite what I was looking for. As my searches became more and more pro maker

movement I came to the sudden realization that I actually had very little

knowledge behind the educational potential the Maker Movement had to

offer. In fact, I was absolutely

clueless. I only knew about the basic functionality of a 3D printer the

additive process through the extrusion of molten plastic to create 3D “stuff”

one designs or borrows from the internet. My understanding of machine of a 3D

printer in a classroom was also very basic. As I had a hard time understanding

the educational impact a 3D printed object can have on a young student. From

what I differed was that a 3D printer was very expensive and printed thing made

of plastic in a relatively short time.

Imagined a classroom setting where a teacher would show students huddled

around a 3D printer as they watched an a outline of plastic become partial

piece of plastic just as the the school bell (to teacher) alerted them switch

activities. Thus leaving the partial piece of plastic to quietly become a bit

more interesting. It sounds cool, but

what are we to do with this new plastic object? I believe most of my thoughts

were like this simply because most of my own 3D printed objects ended in

frustration or as a stiff piece of plastic that was doomed to live on my desk

for who knows when. This made me want to

learn more about the educational uses of a 3D printer as well was the

influences that the printer has had

within the Maker Movement.

After attempting to create a prompt

form my arguments I often found myself wondering what I actually knew about the

Maker Movement. I have found myself only accepting the phrase as it is makes –HA

puns!- it way into my everyday routines through class lectures and news feeds.

It has been a phrase that has just appeared before me. Nor did have I question

the presence of the phrase or the culture behind it. I just though it was “cool”

that one can use 3D printers to make “stuff”. Luckly I have grown much more

aware of the situations before me as I further my education within the strong

emabrace of the Maker Movement.

Many assume that Maker Mvement is a phenomenon

that emerged in the late 2000s. This

however is false as the emphasis for a more hands on education can be found

through out history. Specifically the work of Seymour Papert truly focuses on

the power that an education through doing is much more effective than that of

the standard-sit-at-desk-listen system that schools have. Parpert began to

stress education through the power of doing soon after he created a set of

working gears. “ ” While reflecting on

his work, Parpert hoped that others would also be willing to work on creation

projects much like his own as it helped him learn skills that were necessary

for completing his task of recreating the gears.

With a new appeal and interest in the

Maker Movement I began to look at the research of others on the subject matter.

A book by Sylvia Martinez quickly caught my attention. Her book, Invent To Learn: Making, Tinkering, and Engineering in the

Classroom the versatility of the book was quite useful

as it argued for the importance of making things and “ progressive education”

in the modern classrooms. Interestingly enough Martinez’s push and passion of a

the significance of the Maker Movement is extremely evident as her piece sounds

more like “how to integrate making in your classroom” as it is addressed to

other educators who also attempting the push for Maker Culture within their own

school and districts ( a section is even devoted to educating someone how way

to handle any and all nay-sayers of the Maker Movement!)

POST 5

The Mind and Methods of an Engineer.

Industry City

The trip to Industry City was very satisfying and was fairly eye opening.

I say "eye opening" because of the trip to Makerbot was insight to how a modern manufacturing plant may function in NYC. Simply because a corporation the size of Makerbot, usual do not have their operations somewhere that isn't as economically gripping as a place as NY as appose to an area with much lower rent( like the midwest or even China).

A facility in a different location is likely to have the entirety of the production of their products. That was not the case at Makerbot it was evident that the faculty in Brooklyn was very specific to one or two aspects of production of the 3D printer. However, It wasn't as "manufacture-y" as i thought it could have been.

I was also shocked to hear that the employees of the assembly line was always in flux as many quite their jobs due to wages and the geolocation of the plant itself.

Their building process is rather interesting and probably efficient to an extent, but what was very concerning was that our guide was a bit hesitant when it came to selling and producing for a public that didn't quite understand the fields. It felt like they were simply shoving information at people and hoping that it sticks in some way. I simply find it concerning that an industry is trying to superimpose itself to the general public I say this with public schools in mind, as Makerbot said that their main targets are large firms and educational institutes of all levels. I see that comeInstitutes are embracing the "maker movement" with open arms and are incredibly excited to begin productions of their own; I do see that the movement can cause difficulty for some lower education institutes. I find difficulty in understanding why schools are being targeted by a company such as Makerbot. I say this because I do not see the necessity of a 3D printer in a elementary schools ( though it can make sense in middle and high school, as the have finer focus on skill and career development ) as the educational use of a 3D printer is currently low. I don't see use at the moment, but I can foresee that they will be of use once development and curriculum grow to include the #d printer in the class room. I wonder if the these institutes feel ready to embrace the movement or are they being persuaded to think that they are ready by companies making theoretical uses for their products just to find more clientele

A facility in a different location is likely to have the entirety of the production of their products. That was not the case at Makerbot it was evident that the faculty in Brooklyn was very specific to one or two aspects of production of the 3D printer. However, It wasn't as "manufacture-y" as i thought it could have been.

I was also shocked to hear that the employees of the assembly line was always in flux as many quite their jobs due to wages and the geolocation of the plant itself.

Their building process is rather interesting and probably efficient to an extent, but what was very concerning was that our guide was a bit hesitant when it came to selling and producing for a public that didn't quite understand the fields. It felt like they were simply shoving information at people and hoping that it sticks in some way. I simply find it concerning that an industry is trying to superimpose itself to the general public I say this with public schools in mind, as Makerbot said that their main targets are large firms and educational institutes of all levels. I see that comeInstitutes are embracing the "maker movement" with open arms and are incredibly excited to begin productions of their own; I do see that the movement can cause difficulty for some lower education institutes. I find difficulty in understanding why schools are being targeted by a company such as Makerbot. I say this because I do not see the necessity of a 3D printer in a elementary schools ( though it can make sense in middle and high school, as the have finer focus on skill and career development ) as the educational use of a 3D printer is currently low. I don't see use at the moment, but I can foresee that they will be of use once development and curriculum grow to include the #d printer in the class room. I wonder if the these institutes feel ready to embrace the movement or are they being persuaded to think that they are ready by companies making theoretical uses for their products just to find more clientele

POST 4

Challenge:

The hanging planter that happens to also be pretty cool to look at.

Why? I would like to bring together plants and digital fabrication together in order to harmonize function (and possibly aesthetics) in an interior environment. This most due to my new interest in the botany. Why not combine it with 3D printing? Hanging planters are cool! So are sculptures!

Let's Combine These!

Possible Constraints

Now the real challenge it creating this "planter" is to make it appropriate indoor environment i.e. fabricate at a reasonable scale so that it may hang safely, but not so complicated that it makes maintaining the mechanism (or plant) a chore or a hassle of any kind. Another constraint i foresee is time to print and printer(s) use of the machines available can be an issue when multiple users are interested in 3D printing.

R+D:

After doing some research I can see that many projects of a similar nature - no pun intended - seem to be 3D printed in a single session and are rarely printed in sections. It is comforting to know that most of the projects are also designed for a range of plant and plant sizes. But other projects that tend to sprint in pieces seem to print fairly fast as they sections are usually printed in different printer at a time. It also seems that many of the projects are created in Autodesk 123D or even autoCAD. This should be interesting with my Maya background. I also looked at many kinematic sculptures and watering mechanisms people have created. I think they have likely inspired what I have brewing in my cranium.

Alexis, What are you brewing in that cranium?

I'm glad you asked distant internet view!

I am planning to make a 3D printed plant perch that is to hang from a ceiling! I aim for a medium-ish planter in parts to cut time of print and capitalizing on resources. As for innovations I will design the planter to be kinematic when it comes to watering, that and it will pretty cool to look at.

Prototyping?

02/25/16

Start on paper prototype.

iterate

Paper again!

iterate

Paper again!

iterate

Paper again!

02/26/16

Move to 3D modeling software.

Finish model.

02/27/16

print prototype sections

Iterate (as many times as necessary)

02/29/16

begin final.

Print sections 1 and 2

Print sections 3 and 4

Print secions 5 and 6

03/01/16

make adjustments

Assemble

Hang

Place plant

POST 3

POST 2

The Printer Process!

Well I 3D printed new taps for my tap shoes!!!

The process wasn't as smooth as i wanted it to be. A few issues I had was trying to figure out the dimensions of the machine as I thought that is was smaller than I anticipated. So the first few of my runs were rather small and took a long time as the default settings in Cura are set to be high quality.

The first print took 30 mins and was about 5mm in diameter. These prints were small because i assumed that the scale created in my model would be exported as well.

After a while i figured out how to use the scaling tools in Cura as they are fairly accurate with scale. I set my height to the a measurement I used in the model. The layer size was propionate to the print time and quality of the print, Since i wanted a low-res print i went with a layer of 0.20mm (max is 0.25mm). The print was 70mm X 120mm X 6mm in scale and took about 0.9 hours to finish. the hard part of the process was getting the product of of the heated plate as it got stuck and had no intension to move. i waited 10 mins to allow a cooling of the bed. the applies gentle pressure with a screwdriver to POP the product off of the bed.

time to check if the fit!

For Future Users:

Remember the scale and detail of your print as it may help the process be more efficient.

ALWAYS CHECK YOUR SETTINGS BEFORE SAVING G-CODE AND STARTING YOUR PRINT!!

No trial is the same. make sure you have plenty of time to troubleshoot when needed.

POST 1

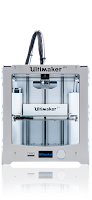

#Ulitmaker #2

Though I have some experience with 3D printing, I have decided to tackle the printers we have at NYU since they tend to break often and need a further understanding to be properly troubleshooted. ALSO it is pretty fun!

Communities!

The technology of 3D printing is still farily young have as an incredible amount of followers and such related peoples. As the Ultimaker 2 is an Open Source machine it has one of the largest forum and community built around it.

https://ultimaker.com/en/community

https://www.thingiverse.com/

Features!

Bulid Volume:

8.8 X 8.0 X 9.0

A Cute LED Screen

Fused Filament Fabrication

One Extruder with a Max. Resolution of 20 Microns

SD Card Slot

ABS and PLA Supported

Specs!

Other Popular 3D Printers!

Makerbot ______

Formlabs Form 1+ ( this a resin printer!!)

XYZprinting Nobel 1.0 ( Another resin printer)

HOW DOES A 3D PRINTER WORK??

Glossary!

https://ultimaker.com/en/tips-tricks/11720-terminology

No comments:

Post a Comment